Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.

1894

Jepson & Co Ltd began in a workshop at 42 Holly Street, Sheffield in 1894 where Mr George Henry Jepson worked as a sign writer while his wife ran the tobacco and sweet shop at 54 Division Street.

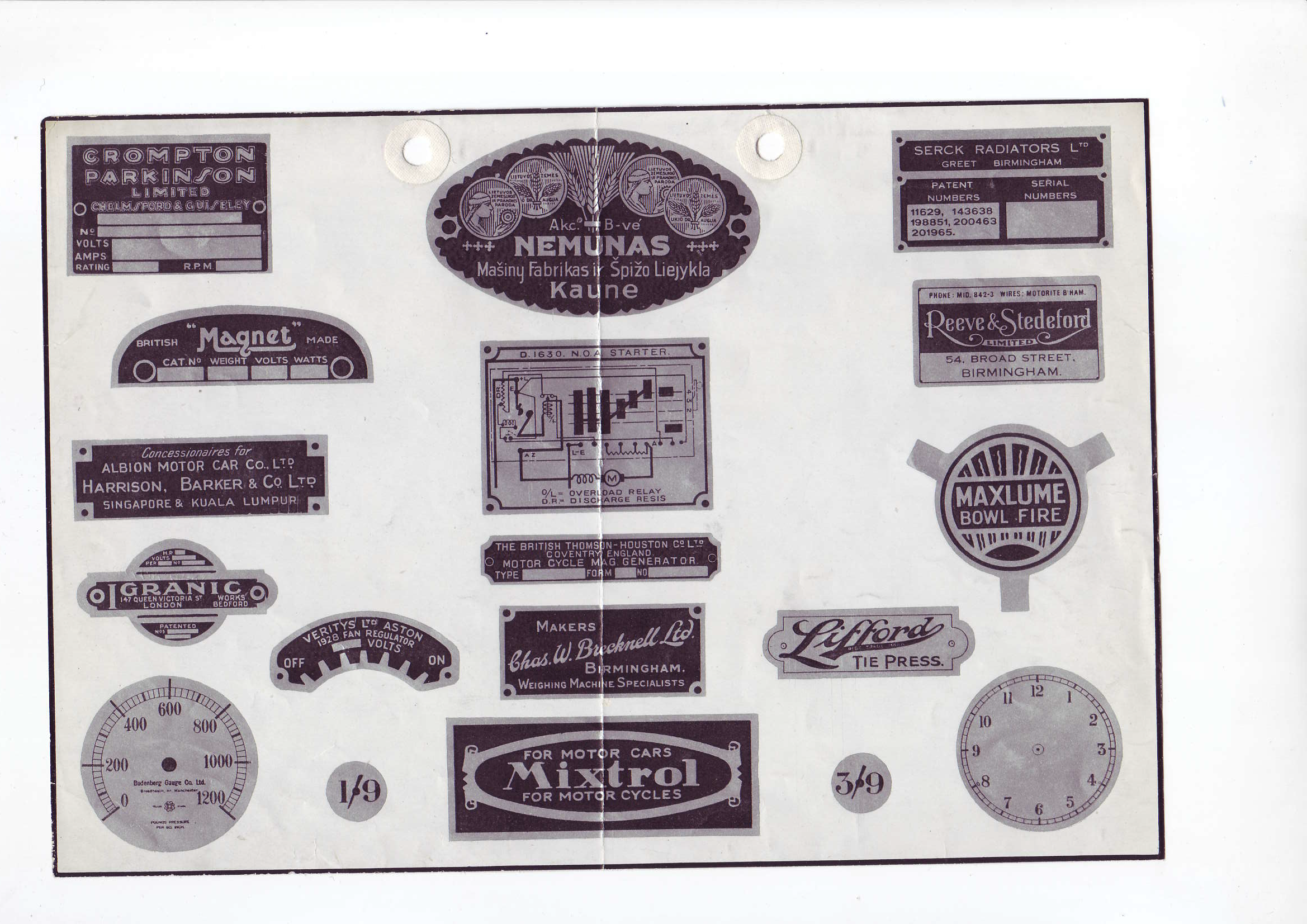

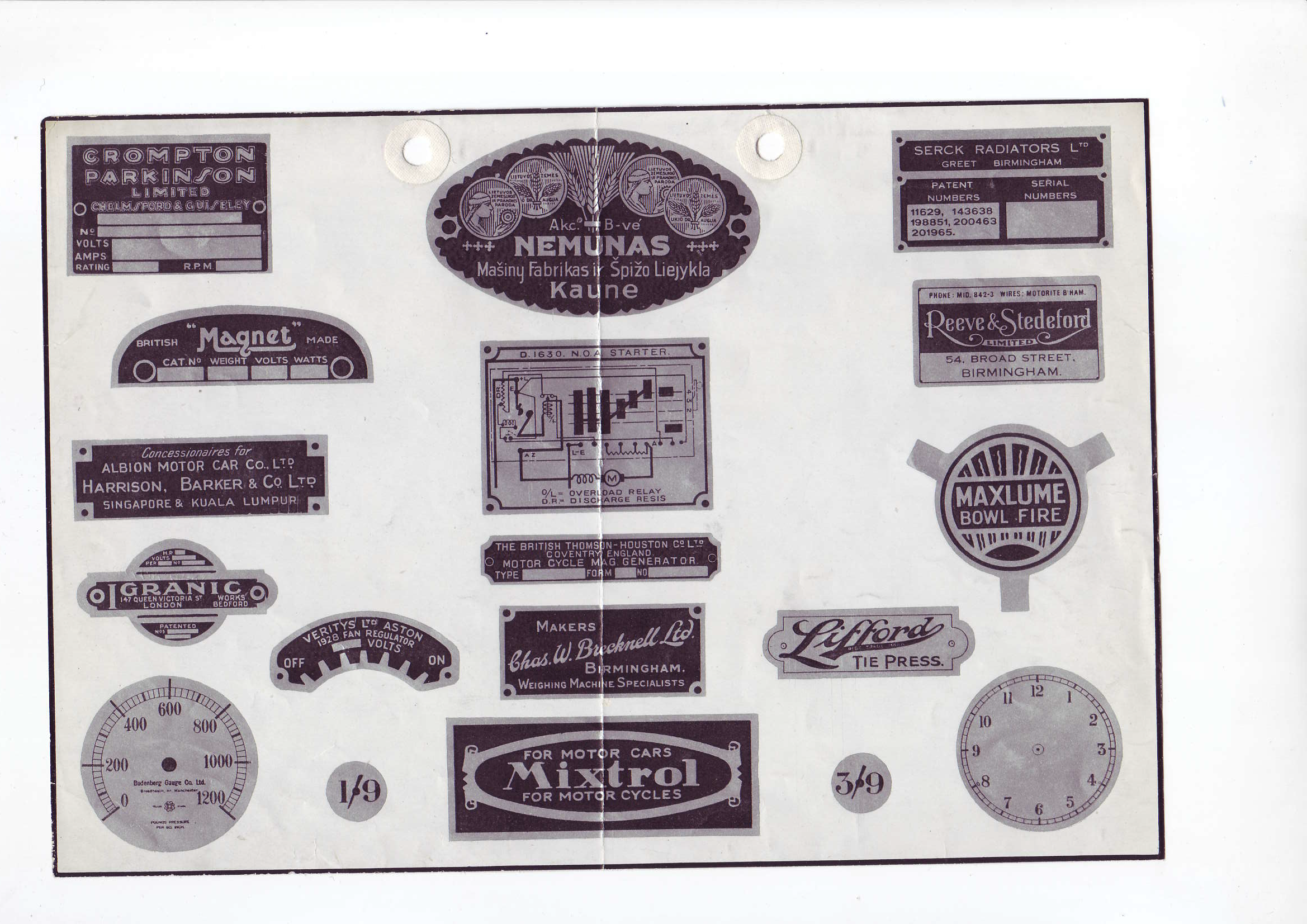

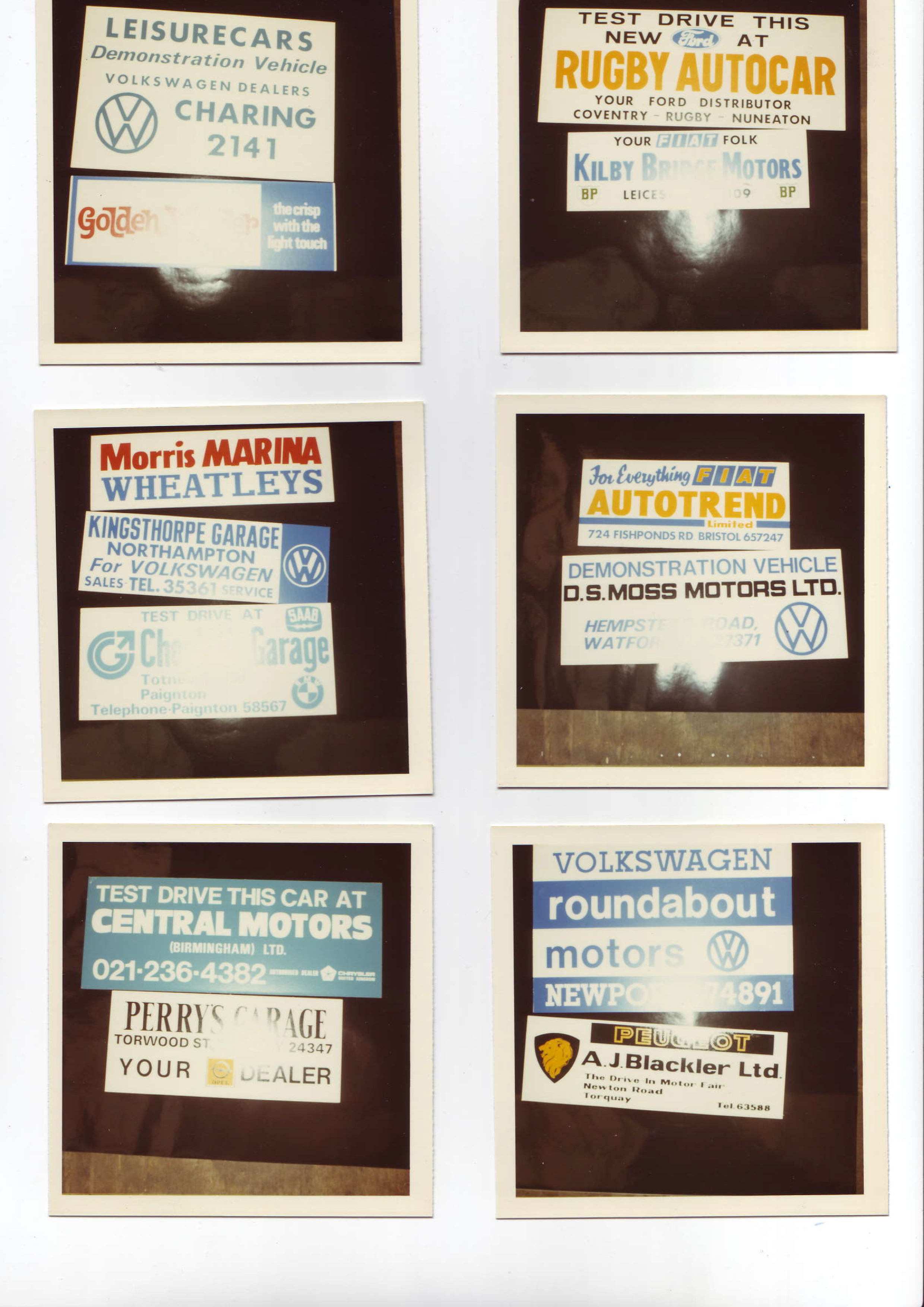

The business moved once again this time to 103 Button Lane and from there on the business was known as Jepson & Company which specialised in hand written shop fascias and signs for railway wagons at 1/6d per truck. They also made cut-out wooden letters, show cards and tin shop window tickets.

1905

In 1905, motor vehicles were required to be licensed to be on the road which led to an influx of work for Jepson & Company. Vehicle owners were required by law to display their registration mark and this was done by hand painting the white digits onto wings and radiators.

As the company grew over the next few years, they found themselves in need of a larger space - the new location being Ox Ivory Works at 20-22 Wellington Street.

The next step to continue to grow as a company was a litho printing machine, which was converted to print onto the tinplate sheets used for making multi-coloured shop window tickets (signs) for butchers, bakers and green grocers. This was the first step into mass production.

1910

In 1910, Jepsons was incorporated into the Companies Act and has since been known as Jepson & Company Limited.

To continue growth, Jepsons acquired a local company – Sheffield Novelty Nameplate Company. This was to improve product lines - brass letters and digits that can be made into tinplate signs, with a baize cover and wooden frame. The techniques used for the signs were developed into embossed aluminium number plates, and later replaced the hand painted method.

With registrations numbers being displayed on plates, as opposed to directly onto the vehicle, they began to supply number plates to garages via post. While Jepsons adapted the embossed style of making number plates, other companies were producing cast aluminium plates which were attractive but also heavy and expensive to produce.

Trade was monopolised by Homo Ltd of Lowestoft and Charles Wright Ltd of London, whom the number plate font was later named after, and between them supplied the eastern and southern parts of the country.

1914

When The Great War broke out in 1914, the manufacturing industry was disadvantaged, as vehicle production virtually came to an end, therefore there was no need for number plates.

The company maintained itself through sub-contracted war needs such as spraying and assembling steel helmets. Following the conclusion of the war, the British army was demobilized and eighteen members of the Jepsons workforce returned including George Arthur, the son of Mr Jepson.

Not long after joining the company, George Arthur sought ways to develop the printing method and he ultimately decided that the printed tinplate tickets were expensive and that a superior product could be achieved by printing onto a white celluloid sheet.

1930s / 1948

Jepsons faced a time of change in the early 1930s as George Arthur Jepson assumed the role as founder, chairman and governing director. From then onwards, to expand and succeed, the primary focus would be the production of number plates.

In the following years, manufacturing processes were improved, including the purchasing of hydraulic pressing machines and stove enamelling systems. This decreased the curing time of painted plates from 2 days, to a mere 2 hours using the conveyor belt oven system, with a capacity to cure 1000 blank plates per day.

While production of blank metal plates had become an efficient process, completed entirely in-house, they were still out-sourcing the digits. Jepsons changes supplier of the white plastic and silver aluminium digits to Charles Wright Ltd, Jepson & Company’s main competitor for number plates. Shortly after, due to delivery time and availability issues, they acquired K.W Siddall Plastics Ltd, and included in the sales was an injection moulding machine.

For a time the company endeavoured to make the plastic aerosol caps, however they later ceased production on the caps to focus on number plates.

1966 & 1967

With the business continuing to grow, Jepson & Co Ltd moved to 24 Wellington Street and built a warehouse above it.

Mr Geoffrey Eric Jepson joined the firm as sales director in 1966 and over the following years, the business stabilised and continued to grow.

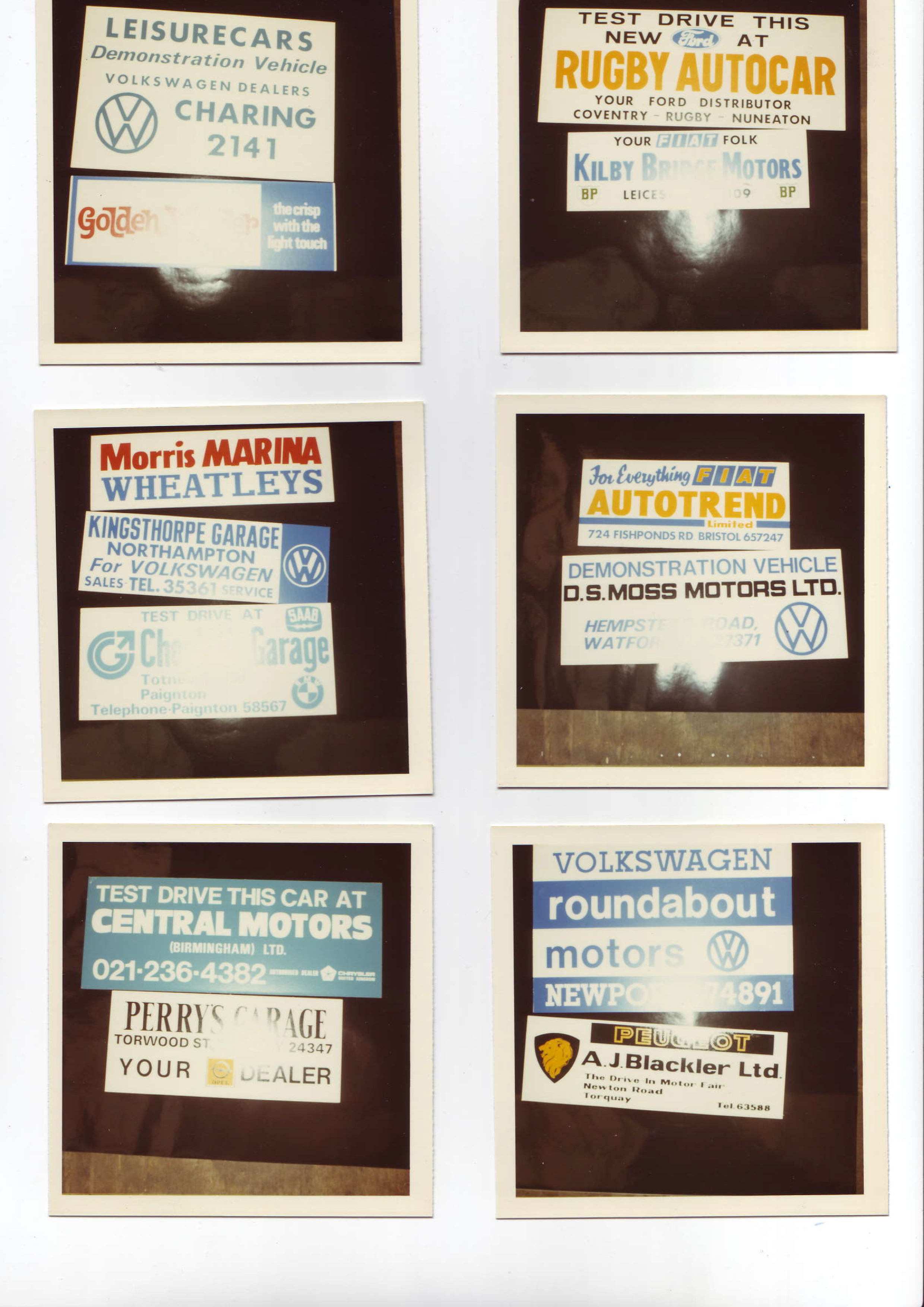

In 1967, acrylic reflective plates were introduced as a new style of number plates allowed on the roads and were proving popular. In 1973, the acrylic and reflective number plates were then ruled as a legal requirement for vehicles. Focus changed to the production of acrylic and reflective materials for number plates, making the manufacturing at Jepson & Co the most advanced with the equipment available.

As industry leaders, they were able to supply customers with reflective plates long before the competitors, which also opened the opportunity to open branches in Glasgow, Bournemouth and London. The main premises in Sheffield were moved to East Bank Road, where Jepson & Co Ltd resides now as one of the world’s oldest number plate suppliers.

1990s / 2000s

In the 1990s, Jepson & Co became the first company to introduce number plate transfers. These were 'kit based' and sold so they could be assembled on-site. This included an alignment tool and individual digits of the transfers so they could be placed over the top of the reflective media.

Going into the 2000s, there was an increase in demand for vehicles. They responded to the industry demand and customer's needs by introducing printers into the product mix.

- Thermal printers were then introduced, which use a ribbon material that is heated onto the number plate reflective. These types of printers are so resilient that to this day, they are still one of the most common methods of printing number plates.

- In the 2000's laser printers were used to making printing plates easier, with a choice of what printer works best for our customers.

Also within the 2000's, Jepson & Co created a system 'Foundry' which was produced in collaboration with a customer to print number plates on-site.

2010s

Going into the 2010s, we are still finding ways to differentiate and innovate, whilst helping keep customers and the industry compliant with legislation and working with best-in-class software - our PlateSync number plate making software. This was initially created jointly with a client as they wanted to create number plates, and share their brand through showroom plates, ensuring brand compliancy at all their dealerships.

Further to this, we went and created PlateSync reports as a way to track what number plates have been printed and find trends in the data that can help reduce wastage on prints.

PlateSync has become our core central concept to delivering secure compliant number plates to customers, with included integrated to our 'Replace my Plates' service and Plate Portal, another innovation. It was also recognised by the Home Office in 2019 for the Security Innovation award.

2020s

In 2020 when the COVID-19 pandemic struck, we looked to our history of supporting frontline workers in the Second World War. We adapted our manufacturing facilities to do the same again for modular sneeze guards to help reduce the spread of the virus, and also won us awards.

We are also the first in the industry to create a Support Bot, which is used to help our customers diagnose any potential issues they may be having with the equipment and use step-by-step guides to resolve the issues. Not only this, we believe we are the first to have a HelpDesk amongst competitors.

JepTab is a new product innovation of acrylic, which is produced in-house and helps to save time for customers when constructing a number plate. Somewhat similar to the idea of a yoghurt pot lid, the tab on the corner of the acrylis can be 'snapped' off, making it a simpler, quicker and cleaner solution.

Even as a 130 year old business, a customer facing approach runs deep within the business. We're always innovating and have done for 4 generations in Jepson & Co's family run business.

Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.

Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.

Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.

Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.

Lorem ipsum odor amet, consectetuer adipiscing elit. Cursus tempor nisl mollis vulputate tempor ad. Convallis interdum odio arcu erat aptent praesent montes platea. Massa nam vitae tortor sagittis praesent nec cursus, senectus aliquet.